15+ Enameling Tips: Safety and Basics for Bringing Color to Your Jewelry

When making jewelry, no matter the medium I’m working with, I like to inject bright, bold colors. When working with metal, enamels become my color injector of choice. And when it comes to enamels—there are lots of ways you can approach this art form. Before you get started enameling jewelry, it’s important to understand the safety and basics of working with this medium.

Get fired up about torch-fired enamel!

Basic Supplies for Torch-Firing Enamels

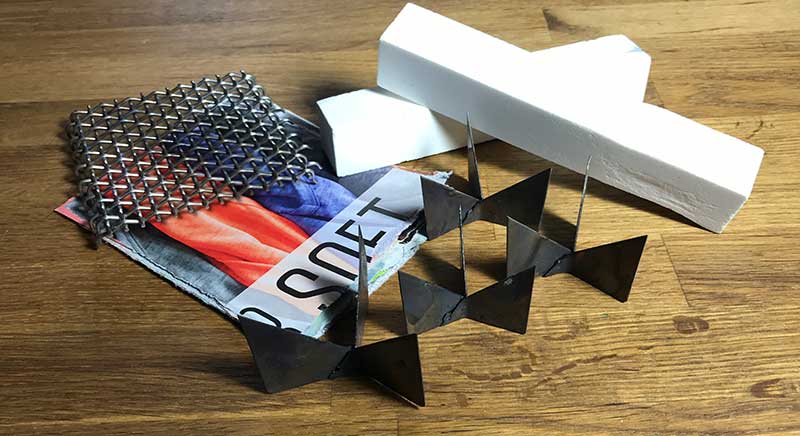

There are a few basic tools you need when torch-firing enamels.

- butane torch

- 9” tripod with stainless steel mesh

- two sifters

- fine-pointed paint brush

- metal spatula tool

- tweezers

- 10 plastic pipettes

- 11 pouches of powder enamel

- one bottle of Klyr-Fire

A few other things I like to keep handy are a good metal cleaner, quartered recycled catalog pages, trivets to support the work I’m enameling, butane for the torch (or a kiln if the day calls for enameling in this manner), and alundum stones or other grinding tool to help remove excess enamels after firing.

Enameling Safety First

When working with enamels, it is paramount that you adhere to general safety guidelines as well as the following list (excerpted from a previous article I wrote):

- Work in an area with good ventilation.

- Don’t eat or drink anything where you will be doing the enameling (particulates could wind up in these items and then inadvertently be ingested).

- When sifting the enamels, wear a dust mask; a particulate respirator is recommended.

- Change your clothes after you’ve completed your enamel work for the day. Use caution if removing your shirt over your face, as some enamel particles may still be present.

- Wear natural fiber clothing when torch firing enamels. Should there be an accidental fire, natural fibers will not stick to you like manmade fabrics would.

- Clean throughout the enameling process so you do not add particles of something to something else—e.g. introducing fire scale to your enamel jars, or blue enamel into your white enamel, etc.

- Clean up your worktable when you are finished enameling and before moving into a new design project.

- When grinding fired enamels, work with water present. This is not only good practice for the sake of your work but also your health.

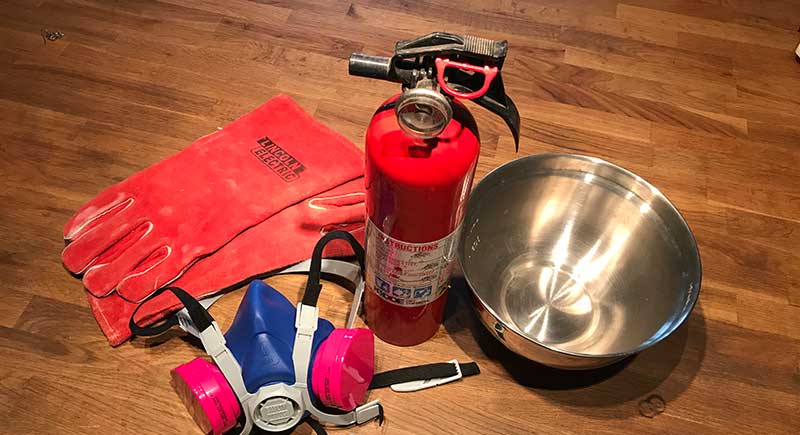

Tips for a Safe Enameling Workspace

- Place a heatproof surface onto your work table.

- Place a trivet onto the heatproof surface.

- Top a tripod with a mesh rack.

- Keep heat resistant gloves, safety glasses, and fiber grip cross-locking tweezers near the firing area—for that just-in-case moment.

- Have a metal bowl filled with water and a fire extinguisher near the firing area for safety in the event of an accident.

- Roll up long sleeves and tie back long hair.

- As always, use good judgment when igniting a torch.

For more enameling safety and torch-firing enamel tips, read Lessons Learned in Torch Enameling Jewelry: You can do it!

5 Basic Enameling Tips

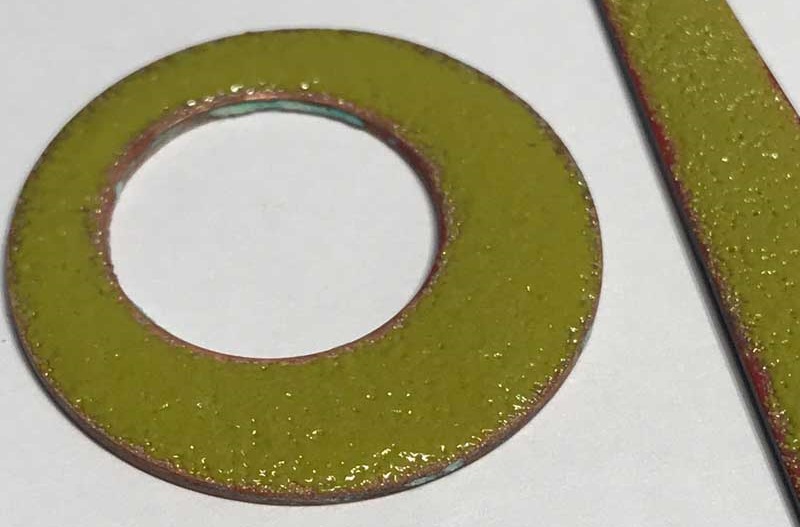

1. Enamels progress through four visible stages when heated:

- Sugar stage looks like you placed a layer of fine sugar on the metal surface.

- Orange peel looks just like you’d imagine. The glass is starting to melt but has a bumpy texture to it (see below).

- Full fuse is when the enamel is smooth as glass (literally!).

- Over fired: Pits begin to form in the surface and sometimes you’ll see the edge of the enamel creeping inward or changing color. This is not necessarily a bad thing, it just depends on the look you’re going for.

2. When enameling metal, depending on the thickness and the technique, it is advisable to enamel both sides of the piece. This will help distribute the stress evenly and help lessen warping, which might occur as the metal and enamel expand and contract differently. These enamel layers are called counter enamel (the under or back side) and topcoat (the layer that is facing forward). Since the first enamel coating will be the counter enamel, heat the blank until the surface of the enamel is at least to the sugar stage. The metal and enamel will be heated again during the topcoat layer, so “sugar” will eventually turn to fully fused. Allow the metal to cool. For basic metal prep information and how to enamel with a torch, read Enameling: Create Flower Jewelry with Enamels, for Color that Lasts Forever.

3. When sifting enamels onto your metal, place a stack of recycled paper underneath your work area. Sift the enamel, allowing the excess to fall away. When you’ve finished sifting, place your enamel piece off to the side, carefully lift the paper you were sifting over, place the jar of enamel powder onto the next layer of paper below, and pour the loose enamels back into the jar. Place both “used” pieces of paper together, fold them into thirds and then thirds again. Place the folded paper into the trash. Folding the papers this way will help contain the loose glass particles and prevent anyone from being impacted by the particles should they help you with your trash.

4. When firing on copper, firescale will form on the exposed surface wherever there isn’t enamel. Firescale is an oxide that is created when the metal is subjected to high heat. As the metal cools, most of the firescale will flake off; any remaining firescale should be brushed off and the metal cleaned again. Tip: When cleaning firescale from your metal, be sure to clean it off in a separate area from your enameling area, or be sure to clean your work surface in between activities. Having firescale in your work may be your choice, but if it isn’t, be aware that it is very obvious when it occurs.

5. It’s advisable to wash your enamels when working with transparent enamel colors in a “wet packing” enameling application, like in champlevé. Washing refers to removing finer enamel particles and leaving behind a consistent size. This effort will yield a clearer enamel finish once fired. To wash your enamels:

- Place a coffee filter into a funnel. Place a small amount of enamels into a lidded jar. Add water and swirl the contents. Allow the enamel to settle; then pour the water (not the enamels) through the filter. Repeat until the water is no longer cloudy after swirling.

- Only wash the amount of enamel powder you feel you will need. Then store any extra in an airtight container. The enamels will start to break down even when stored properly, so use them soon after washing.

For instructions on a basic torch-fired enameling project, read: Double Duty Jewelry Tools: Use Your Disc Cutter as a Washer Maker, Plus a Free Enameled Necklace Project

Enameling Extras

There are many types of glass you can enamel with, including frit, glass threads, and liquid enamel. There are other “add-ons” you can work into a design, like powders, pencils, and decals. For a great listing, read: Torch-Fired Enamel Jewelry: Beyond Enameling with Special Effects, Supplements, and Techniques.

There are many directions you can take enameling. From basic colors to patterned surfaces to whatever your imagination (and the materials) will yield. The wonderful videos and workshops by industry experts are a great place to find inspiration and information on how to create your next design. Have fun adding color into your jewelry making!

Tammy Honaman

Director of Content, Interweave

-

Sale!

Advanced Metal Clay Series: Faux Cloisonné Enameled Jewelry Using Art Clay Online Workshop with Jackie Truty

$39.99$20.00 -

Sale!

How to Enamel Jewelry, Digital Edition

$14.99$7.50 -

Sale!

6 Fun, Fashion Jewelry Projects Video Download Bundle

$149.94$74.97 -

Sale!

Make Torch Fired Enamel Jewelry Components: Charms, Dangles, and More Video Download

$24.99$12.50

Join the Conversation!